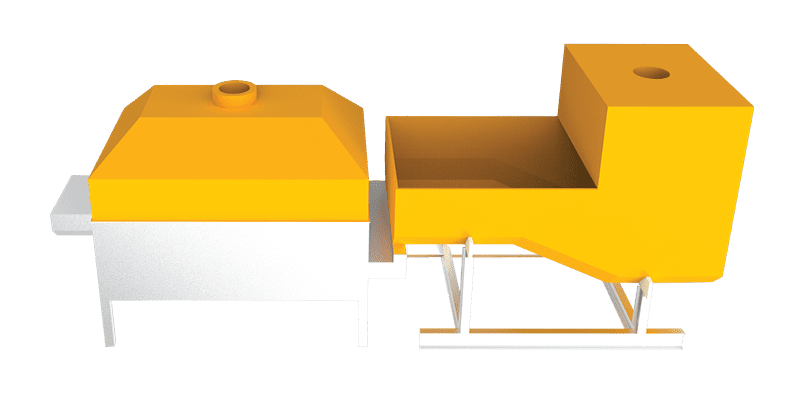

THERMAL RECLAMATION SYSTEMS

The thermal sand reclamation is a system developed to accomplish the recycling of the foundry sands. The system is based on heating the mold sand particles coated with resin up to 630°C. The most significant advantage of the thermal reclamation system is recycling of 90% of reject sand as now, thus reduction of detrimental effects to environment and contribution to the economy.

Advantages of Our System

- To have a fluidized bed systems

- Input the sands from the fluidized bed thermal reclamation are exposed to abrasion and the pointed corners decrease to be more rounded granules.

- To have a Pre-heat area,

- To have a air economizers

- The inert and organic components in the sand are reduced to trace amounts.

- Recycled sand granulation is obtained similar to new sand properties.

- The sand grain surfaces are rounded with maximum efficiency.

- Optimum heat and material transfer with ensures minimum wear on the sand surface.

- Recycled sand shows the same of new sand or better properties.

- Pre-heat and air economizers ensure a minimum energy saving of 12%.

- The flue gas is washed in the liquid flushing system or the dry dust holding system and the emission of the flue gases are zero wherever.

Sand parts of before reclamation

Sand parts of before reclamation