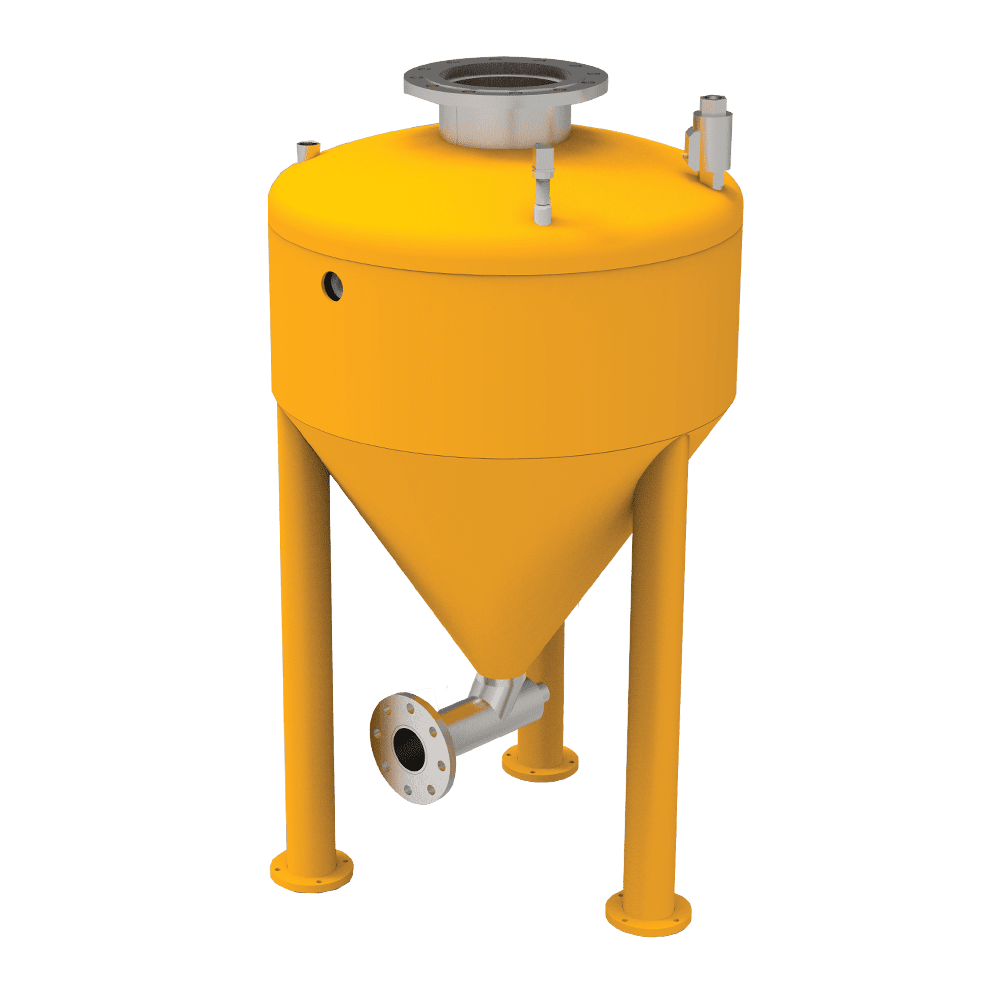

PNEUMATIC CONVEYORS – SENDERS

- Our pneumatic conveying system works with two options in the foundry, mining, chemistry, glass, textile, paper and ceramic industry

- Conveying the desired amount by weighing.

- With the help of level sensors, conveying can be done with the amount of pneumatic converyor’s capacity.

- The sand to be conveyed does not clog up the pipes in the system.

- Since the pressure of the pipe used in the delivery system is 4 bar, the abrasion effect of the sand decreases in the pneumatic conveying.

- Pneumatic conveyors do not pulverize and decompose the physical properties of the sand.

- System reduces the amount of dust in the hopper.

- System reduces consumption of resin and hardener

- The movement of sand can be checked visually

- The amount of ingredients within sand can be calculated via weighing system.

- According to the density of sand, air pressure settings are optional.

- While the sand is being conveyed, there is no fragmentation and thus the dust is prevented from being pulverized.